Fully automatic cells production line

Greenlakesolar solar cells have the production capacity of various models, including 156, 166, 182 and 210 specifications. Each solar production line can produce one cell in 0.8 seconds. The entire line realizes automated loading and unloading operations. AGV carts are responsible for the transportation between processes, and technical workers are responsible for spot-checking the stability of the process technology. Any problems discovered should be adjusted promptly. The cleanliness of the entire workshop should be kept within grade 1000 to ensure the hygiene of the process and the quality of the products.

Full automatic solar panel production line

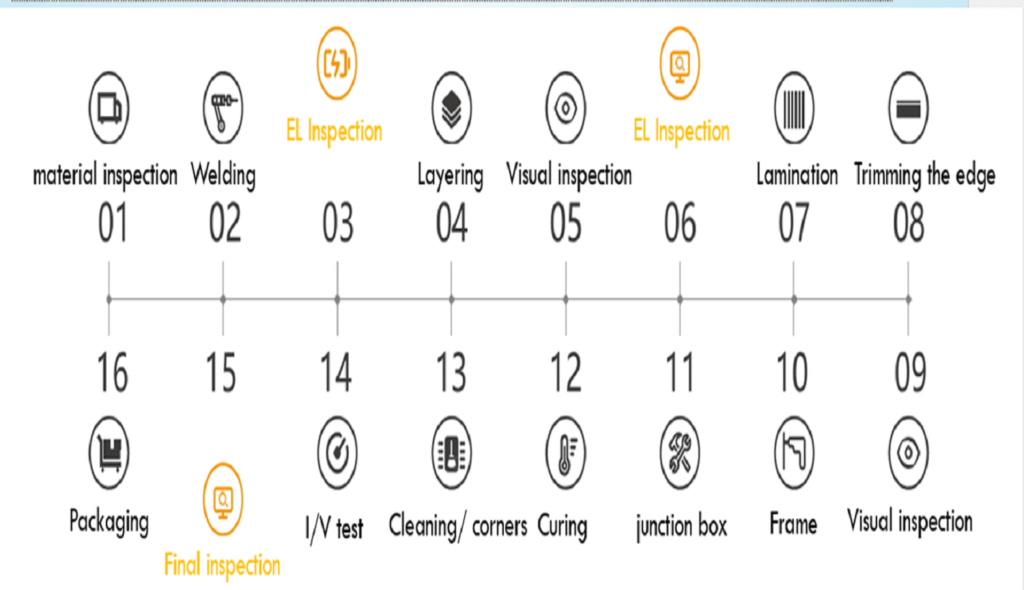

The large-scale component production line of Greenlakesolar is an automated production line. The customized production line is an automated level lower production line, which is designed to meet different customer requirements. At the same time, during the production process, the materials and quality control of the products are ensured to meet the requirements. The large-scale component production line can produce a 630W component in just 16 seconds. We have complete inspection and testing equipment, as well as weather resistance testing equipment, to ensure the product has a lifespan of 30 years.

Reliable process quality control system

Reliable process quality control system

Greenlakesolar During the production process of the product, GREEN has established a reliable and rigorous quality control system. In the component production process, there are three EL detection systems. The equipment conducts automatic detection and automatic judgment, and all the data are recorded in the MES system for processing and feedback. This ensures that the product quality is effectively controlled. Each product has an “identity” record. Only fully qualified products can be manufactured and delivered to customers.